How the spare parts industry can benefit from automated product photography

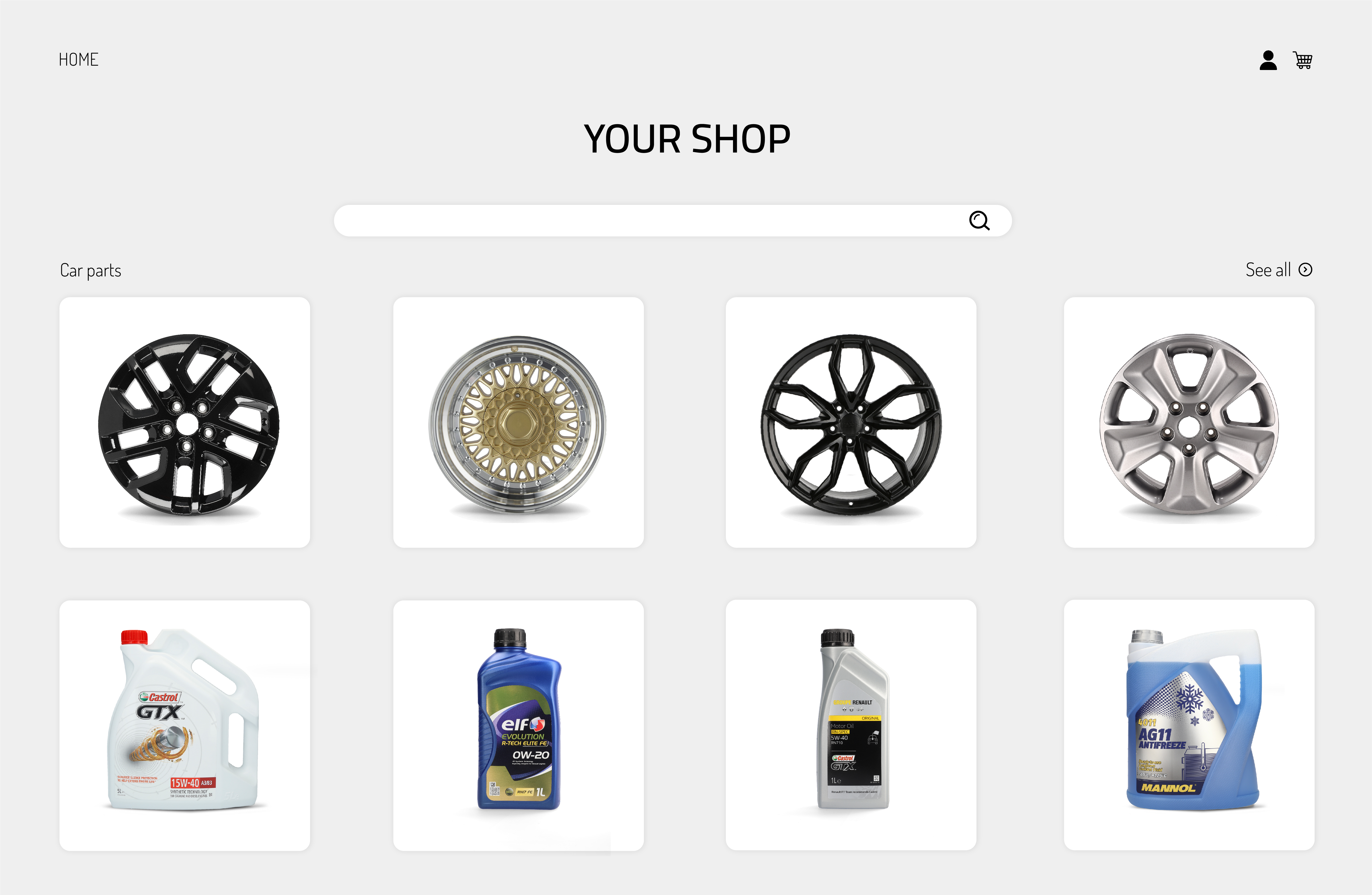

Having an organized and well-structured e-shop takes work. But having an organized and well-structured e-shop with spare parts is even more challenging. So many items, different categories, types, producers, and numbers, yet sometimes, they all look the same. Yup, an efficient inventory management process sounds like a joke right now. How to tackle this problem? With the help of good product photography!

Learn about the prominent challenges in the spare parts industry, how automated product photography may help you lower logistics costs, and more.

How important is product photography in e-commerce?

It goes without saying that product photography is crucial in e-commerce, but it seems even more critical in the spare parts industry.

Because on the one hand, it provides a visual representation of the products and helps build trust and confidence in potential customers. Clear and detailed images differentiate your offer, communicate important information, and meet customer expectations for high-quality visuals, which impacts conversion rates. Additionally, it plays a vital role in social media marketing, attracting attention and promoting brand visibility.

But on the other hand, good product photography can help you immensely with inventory management and overall workflow. Once you have all the products properly sorted and captured with the part number, keeping track of all the items is much easier.

This reduces stress, saves you tons of logistics costs, and allows you to make more informed decisions that can help you sell even more. For example, you can integrate search options and filtering features on your website based on different attributes, like a model or year of making. This way, the customers can quickly find what they are looking for or even compare different items. So faster time-to-market, better user experience, and reduced logistics costs - it’s a triple win!

Challenges of product photography in the spare parts industry

The spare parts industry poses unique challenges when it comes to product photography. Let’s explore how these challenges can impact logistics costs or workflow organization and how automated product photography may be the answer.

Logistics costs

Large and often heavy products are a big part of the spare parts industry. So obviously, transporting these items to traditional photography studios can be costly and time-consuming. Moreover, the size and weight of spare products may require specialized shipping or handling arrangements, further adding to the logistics costs. Not to mention the many returns connected with bad photo quality - this also incurs logistics costs with the transportation, packaging, etc.

How to reduce the number of returns in e-commerce in 11 easy steps? - learn it all from our article.

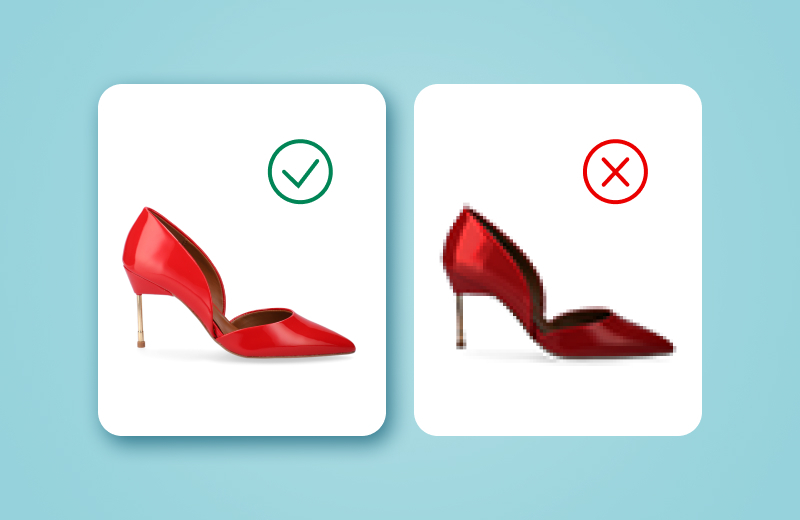

Luckily, with automated product photography solutions, the whole process is done in-house, minimizing transportation expenses and streamlining the photography process. Also, thanks to consistent good quality photos, you minimize the chance of product returns from reasons such as ‘the product doesn’t look like the one on the website.’ Because remember, 75% of online shoppers rely on product photos when deciding on a potential purchase.

Organization of the workflow (labeling the items)

In the spare parts industry, products vary significantly in size, shape, make, and functionality. Hence properly labeling each item becomes crucial to ensure efficient organization and identification during the photography process.

With automated solutions, you can take precise photos, 360° spins, or even videos capturing all the details, while in post-production, you add a part number to the image. Thanks to this, you simplify the workflow and ensure accurate product identification for later use.

360-degree spin of a headlight

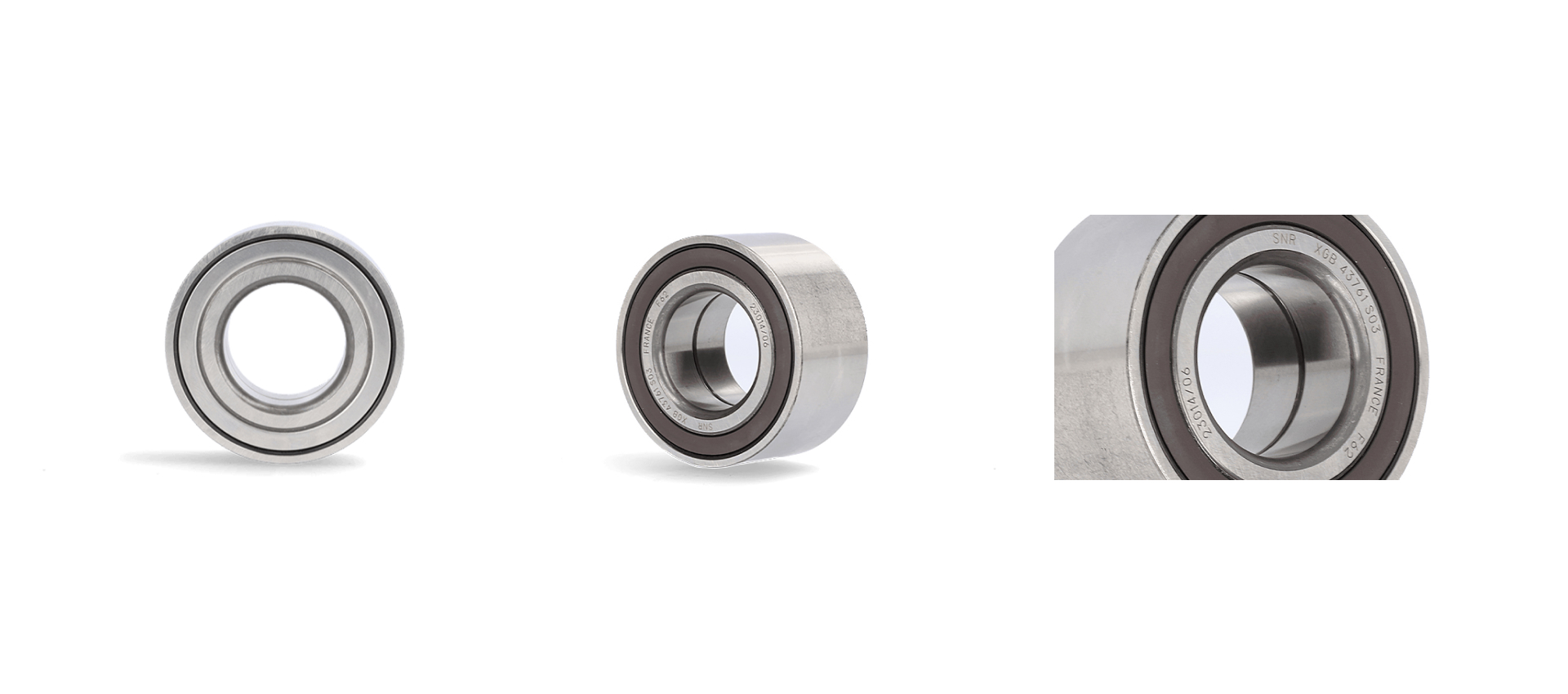

Reflective products

Spare parts and accessories often have reflective surfaces, such as chrome or metallic finishes. Capturing high-quality images of such products can be challenging due to unwanted reflections or glare.

While traditional photography methods may require extensive lighting setups and post-processing efforts to minimize reflections, automated systems incorporate advanced lighting techniques and algorithms to overcome these challenges, ensuring that reflective automotive products are captured accurately without distracting reflections or glare.

A lot of products to capture

The spare parts industry typically deals with a wide range of products. Capturing a large number of those parts manually can be time-consuming.

Automated product photography systems excel in high-volume photography, allowing businesses to capture multiple items quickly and efficiently. These systems can automate the capturing process, adjusting angles and settings, significantly reducing the time and effort required to photograph various products.

Variety of items

Part products come in various shapes, sizes, and configurations. Traditional product photography may require constant adjustments to accommodate these diverse items, leading to a slower workflow and potentially inconsistent image quality.

Automated product photography systems offer flexibility and adaptability to handle the diverse range of service part products. With customizable setups and crafty accessories, these systems can efficiently capture items of different sizes and configurations, ensuring consistent image quality throughout the entire photography process. For example, in Orbitvu solutions, you can create and save templates for various product categories with certain camera settings, camera aperture, and more. In this way, you ensure content consistency.

Learn more about content consistency and why it’s so important for your brand from our article - From Browsing to Buying: Unraveling the Role of Content Consistency in E-commerce Conversion

Mass export of files

In the spare parts industry, there is often a need to export a large number of professional images for various purposes, such as online catalogs, marketing materials, or inventory management systems. Manually exporting and organizing these files can be time-consuming and prone to errors.

Fortunately, automated product photography solutions have efficient file management capabilities, allowing for seamless mass export and integration with existing systems. This streamlines distributing and utilizing product images throughout the automotive industry’s various channels and platforms.

Product photography cost: traditional vs. automated product photography

Once you know that product photography may help you with some of the challenges of the spare parts industry, let’s now compare the cost factors of traditional and automated photography. Do you need to hire a professional photographer, or maybe you can do it all by yourself with an automated photo studio?

Traditional product photography services have long been the norm for businesses looking to capture high-quality images of their products. However, these traditional methods often come with significant costs and limitations.

Equipment and Studio Costs

- Traditional: Setting up a professional photography studio requires a substantial investment in equipment such as cameras, lenses, lighting, backgrounds, and props. Additionally, renting or maintaining a dedicated studio space adds to the expenses.

- Automated: With automated product photography, the need for expensive equipment and dedicated studio space is significantly reduced. You invest once and have everything in-house. Compact and versatile automated systems, like Orbitvu studios, eliminate the need for costly studio setups, saving businesses both upfront and ongoing expenses.

Labor and Time Costs

- Traditional: Manual product photography involves skilled professional photographers and support staff who are required to set up, arrange products, adjust lighting, and capture images. So you have to pay professional photographers and their teams for their work. This whole process is time-consuming and labor-intensive, resulting in higher labor costs.

- Automated: Automated product photography systems drastically reduce labor costs and save time. Once the system is set up, you can place the product inside the device, and the automated system captures high-quality product images quickly and efficiently.

Post-production process costs

- Traditional: After capturing images manually, it’s time for quite extensive post-processing work, including editing, retouching, and color correction. These tasks can be time-consuming and may require the expertise of graphic designers or photo editors, incurring additional costs.

- Automated: Automated product photography solutions often come with built-in image editing features. The systems can automatically process and enhance images, eliminating or reducing the need for manual editing. This reduces the time and cost associated with post-processing while still ensuring high-quality and consistent visuals.

Scalability and Adaptability

- Traditional: Traditional product photography methods can struggle to keep up with the growing demands of e-commerce businesses. Scaling up operations to accommodate larger product catalogs or frequent product updates can be challenging and naturally adds up to product photography costs.

- Automated: Automated product photography is highly scalable and adaptable to changing business needs. With the ability to capture images rapidly and consistently, businesses can efficiently handle larger product volumes and frequent updates without incurring additional costs. This flexibility allows businesses to keep pace with market demands and seize opportunities without constraints.

The benefits of automated product photography

Reduced logistics costs

With automated product photography, businesses can consistently capture high-quality product photos, ensuring that customers receive the exact product they expect. This accuracy minimizes the occurrence of returns, exchanges, and customer dissatisfaction, ultimately saving on logistics costs associated with reverse logistics and re-shipping. Also, accurate and detailed product images can significantly improve inventory management and fulfillment processes.

Improved workflow

By leveraging automated product photography solutions like Orbitvu, businesses can effectively reduce logistics costs by optimizing product images, streamlining inventory management and fulfillment processes, enhancing customer experience through accurate visuals, and minimizing returns and exchanges. These cost-saving measures improve operational efficiency, increased profitability, and a seamless customer journey.

World-class quality photos without experience

When it comes to online shopping, customers heavily rely on product visuals to make purchase decisions. Automated product photography allows businesses to capture detailed and accurate images, showcase the product from various angles, highlight features, and provide close-up views. Especially if these automated solutions also implement 3D imaging and VR visualization. The technologies can create interactive and immersive product experiences, allowing customers to view spare parts from different angles and explore their features virtually.

By providing customers with a clear understanding of what they are purchasing, businesses can minimize returns and exchanges, which translates to saving on the associated shipping, handling, and restocking expenses. This reduction in logistics costs improves profitability and enhances customer satisfaction and brand reputation.

In addition to capturing product images, automated solutions can also integrate post-processing capabilities. This includes tasks such as image editing, background removal, resizing, and formatting. By automating these post-processing steps, spare parts companies can quickly generate ready-to-use product images for various marketing purposes, such as catalogs, e-commerce platforms, and digital marketing campaigns.

Faster time-to-market

Automated product photography solutions are designed to handle large volumes of products efficiently. These systems can capture images of multiple spare parts simultaneously or within a short time frame. With batch processing capabilities, companies can photograph numerous spare parts in a single session, saving significant time compared to manual photography. Moreover, these solutions are easily scalable, allowing businesses to handle increasing product volumes without compromising the time-to-market.

Also, many automated product photography solutions offer integration with e-commerce platforms, such as Shopify or WooCommerce. This integration allows for seamless transfer of product images and data, eliminating the need for manual uploads and data entry. By automating the image management and uploading process, spare parts companies can expedite the listing and marketing of their products on e-commerce platforms, accelerating the time-to-market.

Learn more about the benefits of using plugins in your e-commerce shop.

All in all

Spare parts photography isn’t the easiest one. The product components come in different sizes; they’re chromatic and often seem ‘dirty,’ so the cleaning, lighting, marking, and other things are super important to make them look attractive.

Automated product photography solutions like Orbitvu allow businesses to easily generate and format images to fit the desired specifications. This optimization enhances the visual appeal of the products. It also helps companies present a consistent and professional brand image across different channels.

So are the automated studios a better choice? Simple answer? Yes, they’re. But the truth is, a purchase decision depends on your needs, requirements, and other factors.

Find out how much you can save with Orbitvu solutions and which device is for you.

Articles you may also like

The term Window shopping has been around for decades. Some still consider strolling down the mall’s alleys and simply admirin...

Orbitvu USA is proud to announce its participation in the upcoming inaugural FIN Studio events in New York and Los Angeles th...

The e-commerce market has continuously grown in the past few years and is expected to expand by another 10.4% in 2023. Accord...